The craftsmanship of artificial flowers is very delicate, delicate and lifelike. For example, the thickness, tone and texture of rose petals are almost the same as real flowers. The stems, leaves and flowers made of polymer resin are used after a special bright surface treatment and a matte surface treatment. In the use of floral materials, paper flowers, hand-rolled flowers, silk flowers, forged ribbon flowers, and wheat-wrapped flowers are the main ones.

A. Production of plastic flowers with glue

1. Flower-making: Pour the vulcanized rubber solution into the mold, and then cool it out to make a flower or leaf blank.

2. Coloring Coloring the blank obtained from 1 can be achieved by the following two methods:

(1) Coating rubber: Immerse the blank obtained from 1 in the vulcanized rubber solution of other colors, and then take it out for cooling.

(2) Color spraying Use the spray gun to spray the required color on the blank obtained from 1.

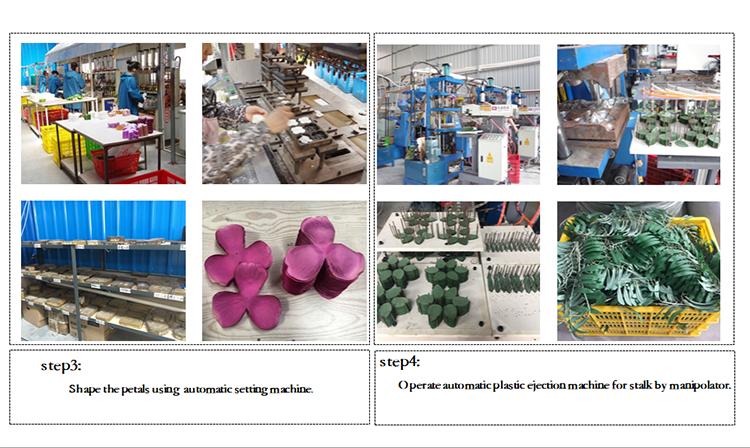

3. Heat-synthesis type Put the colored blank in 2 in the heat sealing machine, control the heating temperature at about 200-300℃, and use the mold to emboss the blank to form a finished product.

4. Assemble and finalize the whole manufacturing process by fixing the finished flowers and leaves after 3 steps of heat-sealing on a plastic rod that is wound by hand or machined.

B. Production of plastic flowers with cloth base

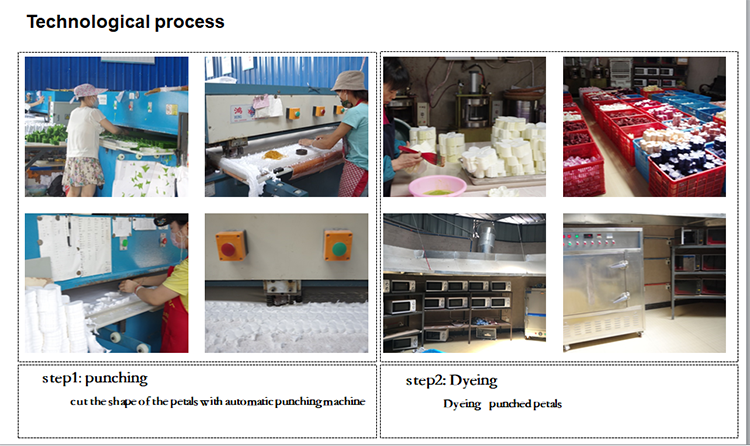

1. Flower type The raw material of this step is pearl cotton, the thickness of which is 0.5-1mm, the pearl cotton is placed in the model of the press to be stamped into a cloth base of artificial flowers.

2. Hanging glue: Immerse the cloth base obtained from 1 in the vulcanized rubber solution, and then lift it out to cool, and the vulcanized rubber is solidified on it to complete the rough production.

3. Coloring Coloring the blank obtained from 2 can be achieved by the following two methods:

(1) Coating rubber: Immerse the blank obtained from 2 in the vulcanized rubber solution of other colors, and repeat the operation of 2 steps.

(2) Color spraying Use the spray gun to spray the required color on the blank obtained from 2.

4. In the thermal synthesis type, the blanks colored by 3 are placed in a heat sealing machine, and the heating temperature is controlled at about 60℃. The heating temperature is lower to prevent the pearl cotton as the cloth base from melting at high temperatures. After the blank is embossed by a mold Form a finished product.

5. Assemble and shape the finished flowers and leaves after 4 steps of heat-sealing and fix them on the plastic rods which are wound or machined by hand to complete the whole manufacturing process.

Product development and production of special colors, special specifications, and special materials, that is, development and production according to customer requirements.